3D Printing in 2025: Transforming Manufacturing, Healthcare, and Everyday Life

Over the past decade, 3D printing has evolved from a niche innovation into one of the most influential technologies of the 21st century. What was once limited to research labs and industrial giants is now widely accessible to educators, designers, engineers, healthcare professionals, and even hobbyists. The growth of additive manufacturing, as 3D printing is also known, has reshaped industries by making production faster, more flexible, and cost-effective. In 2025, this technology is no longer futuristic—it is a vital tool driving innovation and creativity worldwide.

What Is 3D Printing and How Does It Work?

At its core, 3D printing is the process of creating three-dimensional objects by adding material layer by layer, guided by a digital 3D model. Unlike traditional manufacturing, which typically involves cutting or molding material, additive manufacturing builds objects from the ground up, allowing for unprecedented design freedom.

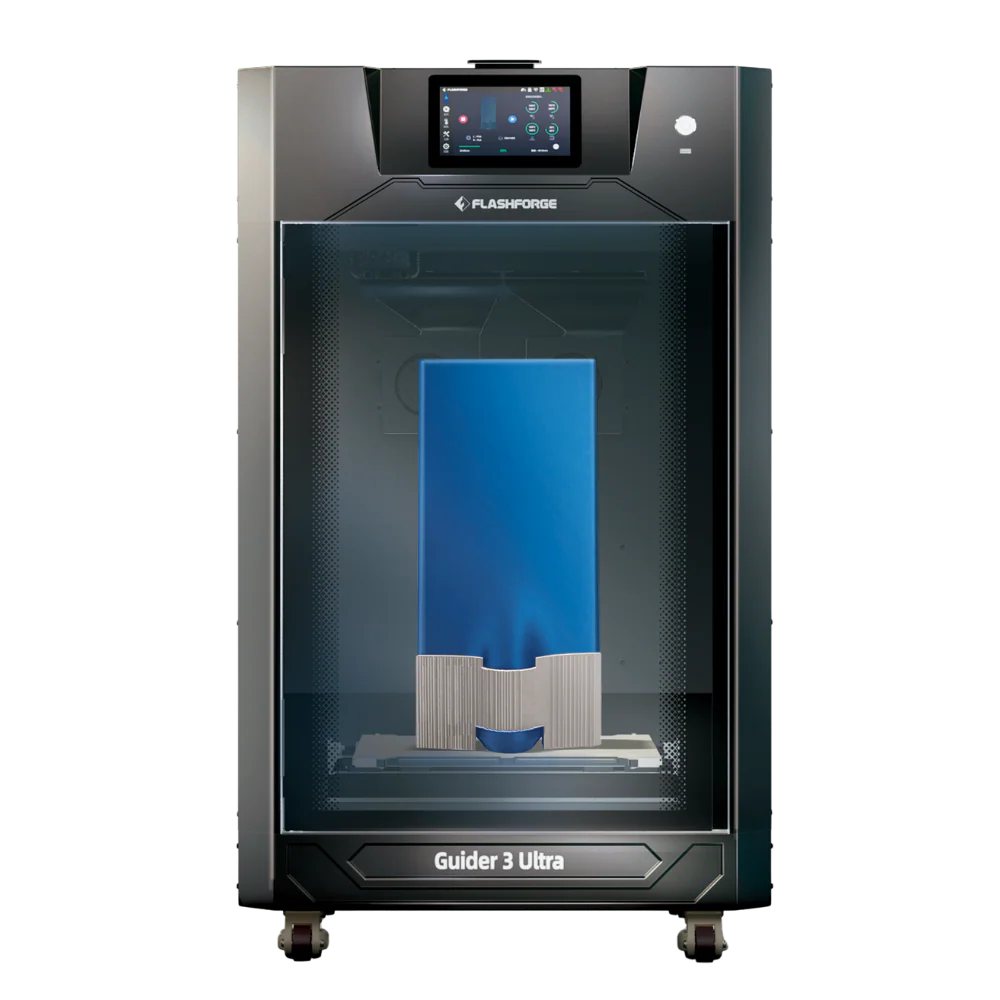

Different methods of 3D printing exist to serve diverse applications. Fused Deposition Modeling (FDM) printers extrude melted thermoplastic filament, making them popular for entry-level and general-purpose projects. Stereolithography (SLA) and Digital Light Processing (DLP) printers cure liquid resin with light, producing parts with exceptional detail and smooth finishes. More advanced technologies such as Selective Laser Sintering (SLS) and metal 3D printing use lasers to fuse powdered material, creating durable, functional parts for demanding industries.

The Evolution of 3D Printing

The origins of 3D printing date back to the 1980s, when the first stereolithography machines were introduced. Initially, these machines were costly and confined to rapid prototyping for industries such as aerospace and automotive. However, the early 2000s brought significant changes as open-source communities and affordable desktop printers made the technology accessible to a wider audience.

By the mid-2010s, 3D printing had entered homes, schools, and small businesses. Today, in 2025, the market has expanded dramatically, offering machines for every need—from hobbyists creating figurines and household items to industries producing medical implants, car components, and even building structures. This democratization of 3D printing has positioned it as a cornerstone of modern innovation.

Benefits of 3D Printing

The appeal of 3D printing lies in the numerous advantages it offers. One of the most transformative benefits is design freedom. Engineers and designers are no longer restricted by the limitations of traditional methods. Complex geometries, lightweight structures, and custom designs can be produced with ease.

Another key benefit is speed. What once took weeks of manufacturing and shipping can now be accomplished in hours or days with rapid prototyping. This acceleration reduces costs, shortens product development cycles, and enables companies to stay competitive in fast-moving markets.

Customization has also become a defining feature of additive manufacturing. From personalized medical implants to custom-fit footwear, 3D printing empowers industries to create one-of-a-kind products tailored to individual needs. This trend is particularly impactful in healthcare, where patient-specific solutions are revolutionizing treatment.

Sustainability is another growing advantage. Since 3D printing is additive, it minimizes waste by using only the material needed for each object. Combined with the rise of biodegradable filaments and recyclable materials, the technology contributes to more environmentally conscious production methods.

Applications of 3D Printing

The versatility of 3d printing has fueled its adoption across diverse industries. In healthcare, it is used to create surgical models, dental aligners, prosthetics, and even bioprinted tissues under development for future regenerative medicine. Aerospace and automotive companies rely on additive manufacturing to produce lightweight yet strong parts, improving efficiency while reducing production costs.

Education has embraced 3D printing as a tool to inspire creativity and problem-solving. Classrooms equipped with printers allow students to turn theoretical concepts into tangible projects, fostering a deeper understanding of science, technology, engineering, and mathematics.

Consumer markets have also grown rapidly. Artists and hobbyists use 3D printers for sculptures, miniatures, cosplay accessories, and household gadgets, turning creative ideas into reality with ease. Even industries like fashion and food have begun experimenting, pushing the boundaries of what 3D printing can achieve.

Challenges Facing 3D Printing

Despite its success, 3D printing still faces challenges. The cost of high-end printers and materials can be prohibitive for some users. Print speed, though improved, may still lag behind traditional mass production methods when scaling large quantities. Post-processing, particularly in resin printing, often requires additional steps to achieve a finished product.

Intellectual property concerns also remain, as the ease of replicating digital designs raises questions about ownership and copyright. Nevertheless, ongoing advancements in materials, hardware, and software continue to address these issues, making the future of 3D printing increasingly promising.

The Future of 3D Printing

Looking ahead, the potential of 3D printing is extraordinary. In healthcare, researchers are making strides toward bioprinting organs, which could revolutionize transplantation. Construction companies are experimenting with large-scale 3D printers capable of building houses quickly and affordably, offering solutions to global housing shortages.

The integration of artificial intelligence and machine learning is expected to enhance the printing process, enabling smarter printers that automatically optimize designs for speed, strength, and material efficiency. As costs continue to decrease, high-quality printers will become even more accessible, further accelerating widespread adoption.

Conclusion: Why 3D Printing Matters Today

In 2025, 3D printing is not just a technology of the future—it is a transformative force shaping the present. From rapid prototyping in engineering to customized medical solutions and artistic creativity, it is redefining what is possible in manufacturing, education, and everyday life.